ID

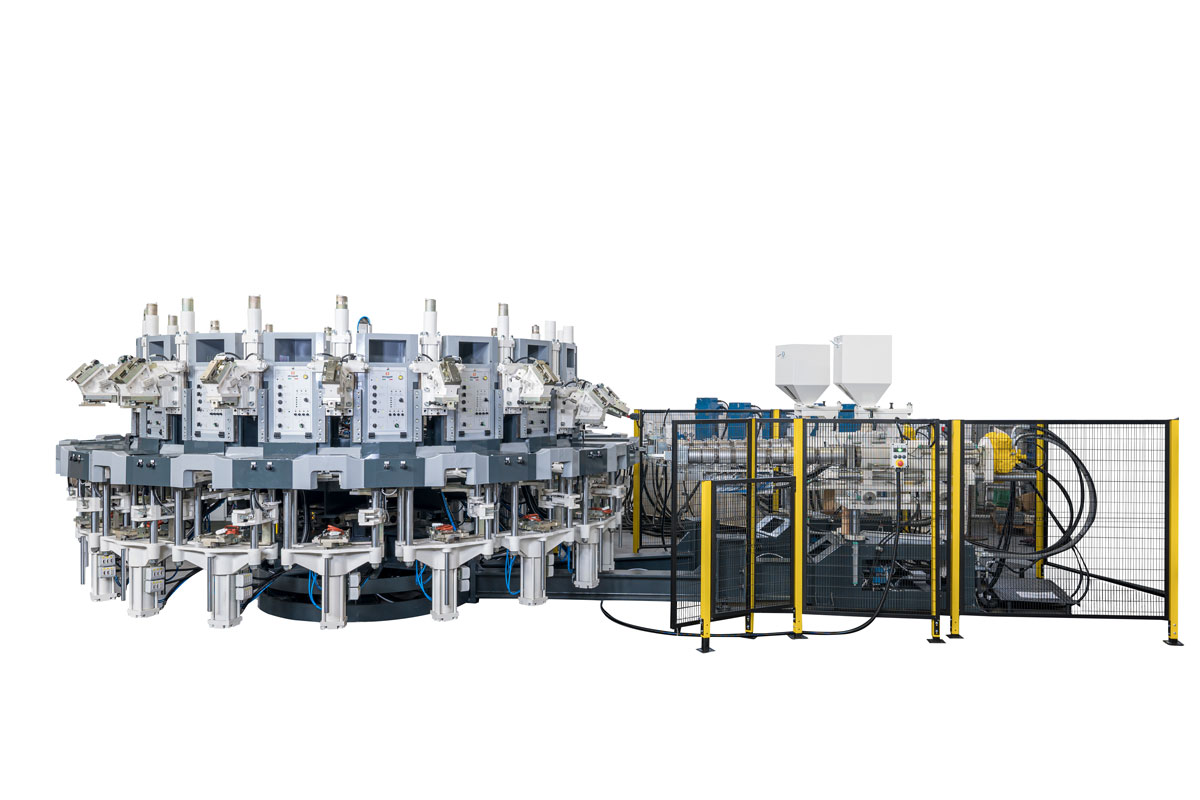

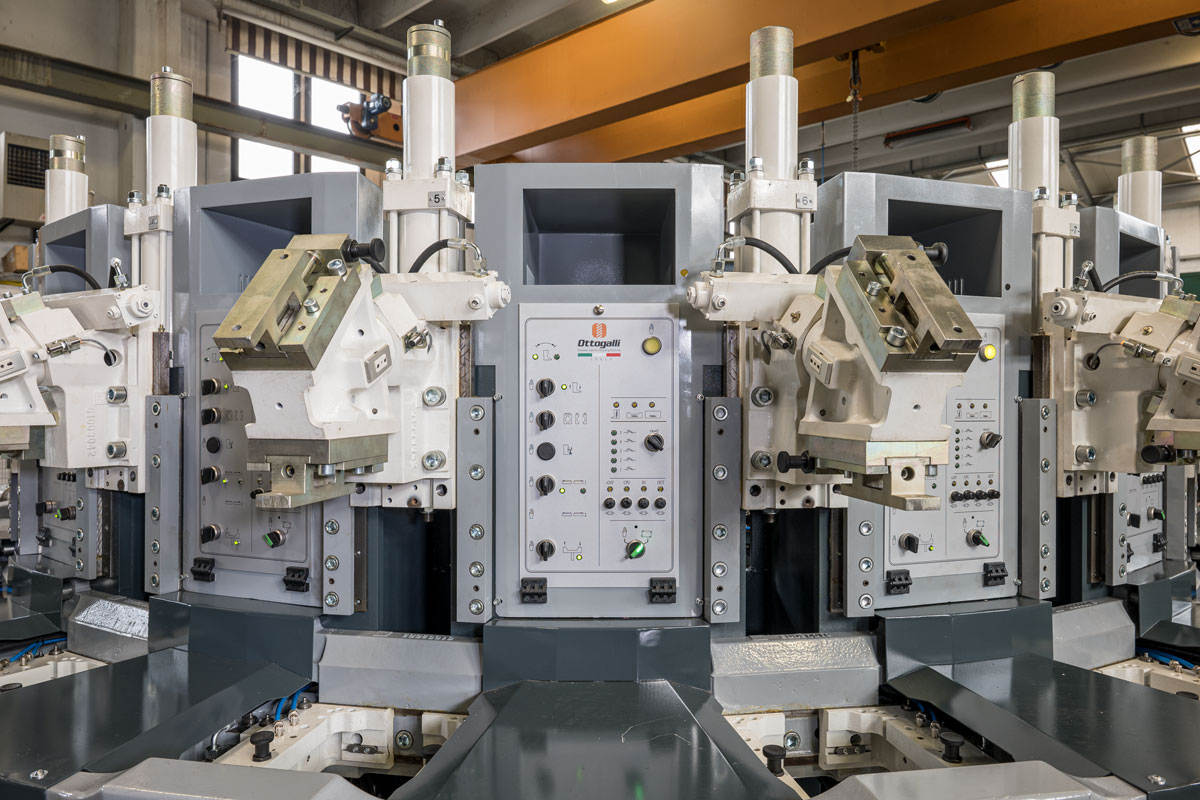

Configuration: Rotary Press

Finished product: Direct Injection on Upper

Material: THERMOPLASTICS PVC TR TPU

Automatic machine for direct injection of soles on the upper, made of pvc thermoplastic materials, tr compacts and multi-color foams.

Equipped with an automatic programmable system by the use of rack and pinion wheel for rotation of the last.

Technical details ID

| Number of stations | n. 12 / 18 / 24 / 36 |

| Number of injectors | n. 1 a n. 7 |

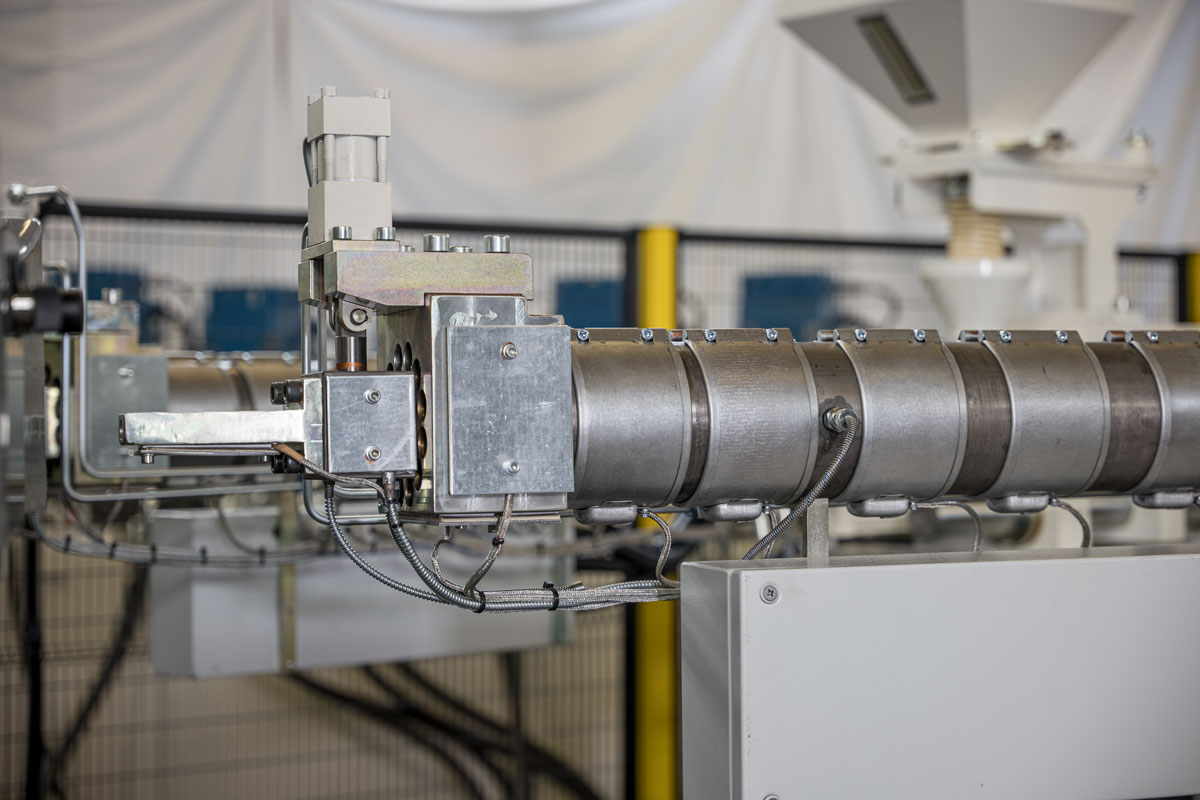

| Diameter | ø65 or ø75 (ø80 mm on request) |

| L/D ratio | L/D 21 / 20 / 18 |

| Injection volume | cc 1150 / 1350 / 1500 |

| Theoretical max injection flow rate | cm3/sec 320 / 360 / 400 |

| Hydraulic Motor Displacement | cc 500 / 500 / 800 |

| Max screw rotation speed | rpm 180 / 180 / 150 |

| Max torque at 120 rpm | daNm 100 / 110 / 115 |

| Standard mold size | Standard |

| Max heating power | Kw 7 per injector |

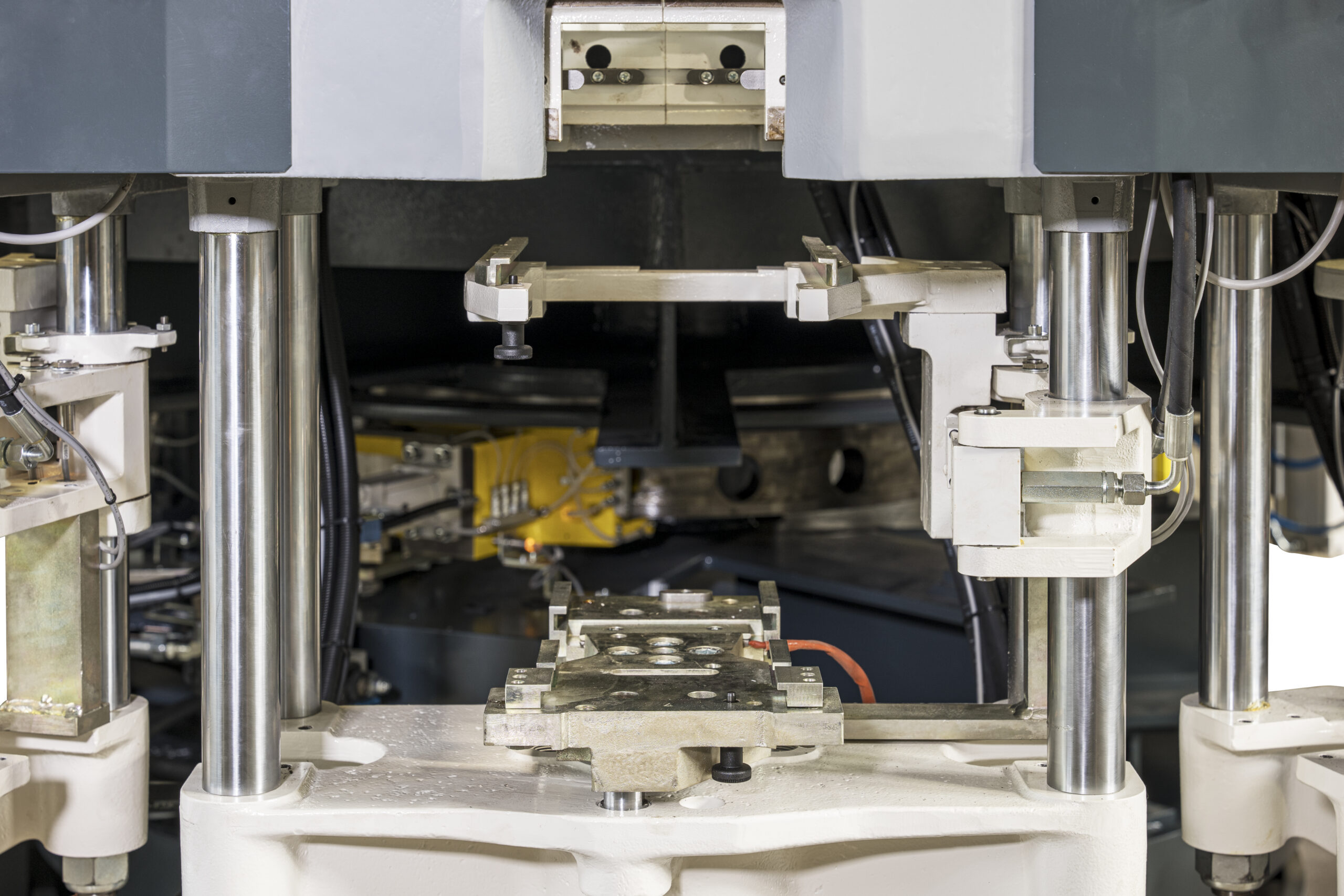

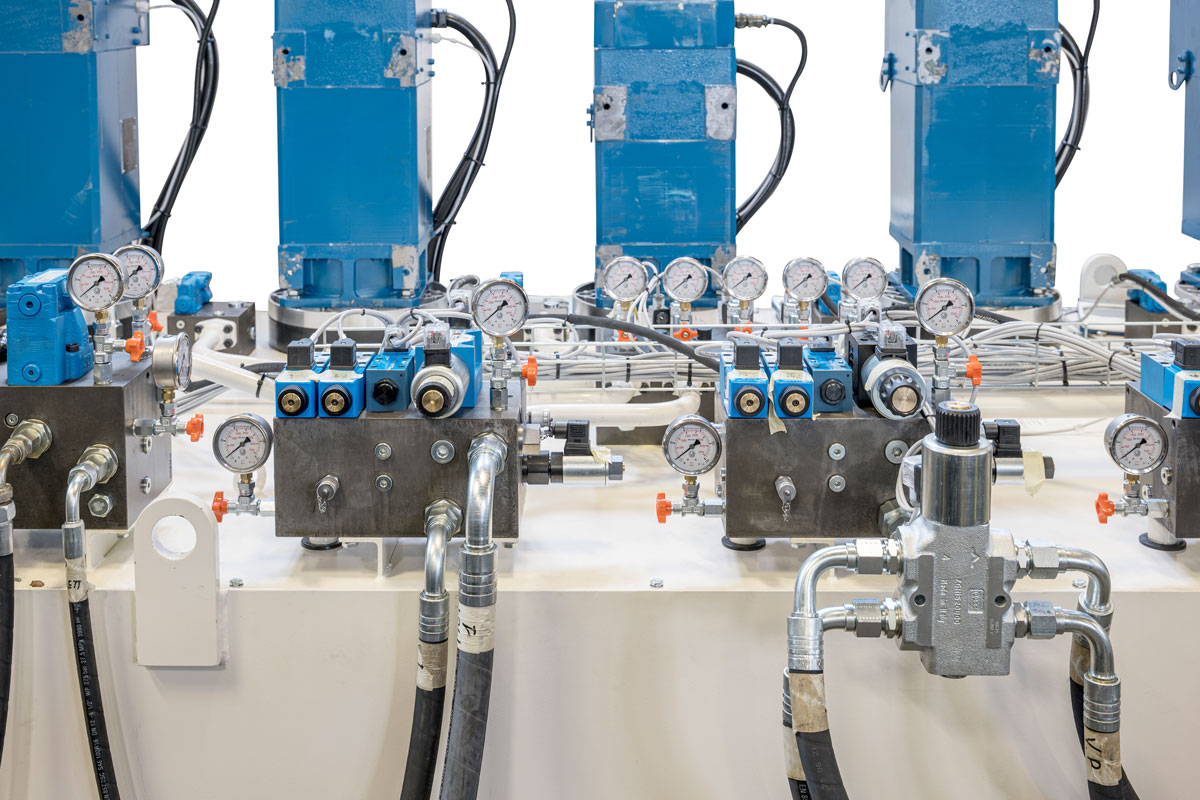

| Force Closing mold holder | Guaranteed by mechanical hydraulic system |

| Automatic Mold Holder Opening | Standard |

| Blowing air into the molds | Standard |

| Mold cooling | Standard |

| Automatic shape rotation | Standard |

| Press closing force | kN 150 |

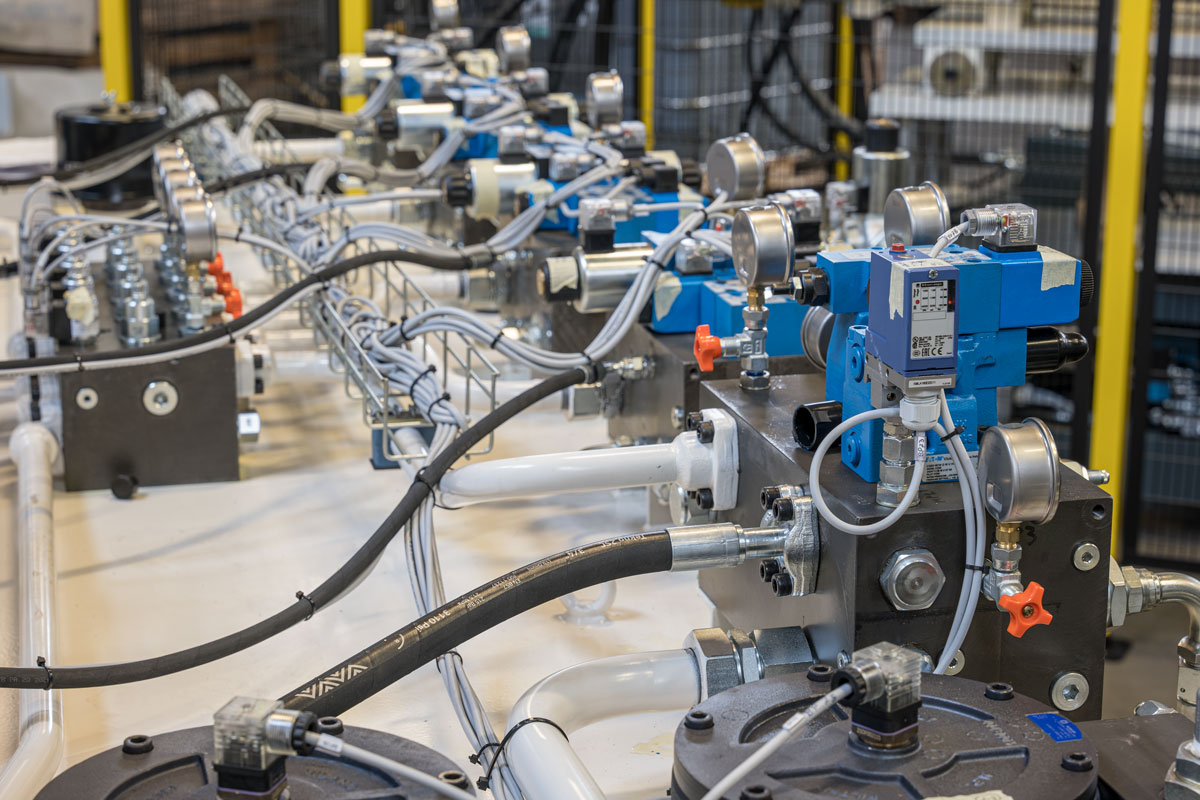

| Energy saving hydraulic system | Standard (Brushless Optional) |

| Maximum service pressure | kg/cm2 150 |

| Proportional flow valves | Standard |

| Proportional speed valves | Standard |

| Electric unit with Plc and Video Touch screen | Standard |

| Total installed power (average for 18 staz. and 3 injectors) | kW 135 (Brushless kW 100) |

| Average consumption at steady state (average for 18 staz. and 3 injectors) | kW 80 (Brushless kW 64) |